| use | This machine is mainly used for processing copper and aluminum busbars of various high and low voltage power transmission and distribution complete sets of electrical and power transformers. It is used for copper and aluminum busbar cutting, punching, bending, folding and other processes. |

| main feature | One machine and three stations are synchronized in one, five-arm punching die set, light source alignment, five sets of self-contained guide and guide sleeve molds, double guide cylinder punching device, punching straight out of waste is not blocked, digital ruler equipped with proximity switch The device, the bending angle is clear at a glance. |

| Station function | Various molds such as shearing, punching, bending, vertical bending, pressing pitting, flat pressing, and pressing cable joints can be interchanged independently in the workstation, and the matching specifications are optional. |

| Electronic control function | Start at any time, stop automatically, save electricity and fuel, equipped with preheating function. |

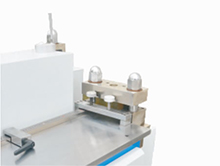

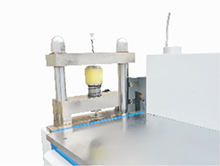

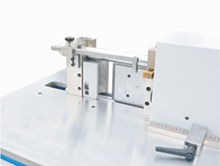

| Bending station | Punching station | Shearing station |

|

|

|

advantage

1. Shearing automatic downward pressure type, upper and lower rubber devices, easy to cut short rows

2. Guide groove, no waste after shearing, small section slope

3. 3-12mm copper and aluminum bars do not need to adjust the blade gap

4. Single arm mold base, pointer positioning, punching faster

5. Double-cylinder blanking device, the lower die is not easy to damage

6. The design of double guide cylinder with three points and one line, the bending angle is simple and convenient

7. The punching has its own waste collection box for smooth waste discharge

8. The digital ruler is equipped with a proximity switch device, which is simple and convenient to adjust the bending angle

9. All kinds of bending molds can be interchanged, no need for professional CNC personnel to operate

10. The cost of this machine is low compared with traditional CNC

The main technical parameters

| Nominal pressure | 3*350KN |

| Bending specifications | 130*12mm |

| Punching specification | Φ4.3-Φ25 |

| Shear specification | 130*12mm |

| Motor oil station | 4KW/22mpa/380V/50Hz |

| Dimensions | 1450*1300*1150 |

| Machine weight | 1.32T |